Solar Vacuum Tubes

| solar tube | |

| 58-1800 | |

| Glass | |

- Technical Specifications

- Features

- Contact Us Now

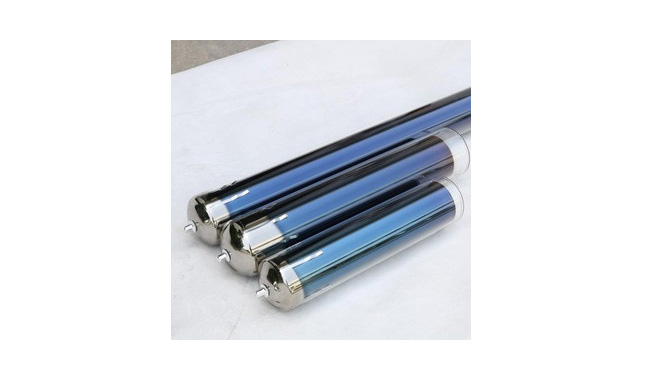

Glass solar vacuum tubes are the key component of the solar collectors. Each solar glass vacuum tube consists of two glass tubes. The outer tube is made of extremely strong transparent borosilicate glass, that is able to resist impact from hail up to 25mm in diameter.

The inner tube is also made of borosilicate glass tube, but coated with a special selective coating which features excellent solar heat absorption and minimal heat reflection properties. The air is withdrawn (evacuated) from the space between the two glass tubes to form a vacuum, which eliminates conductive and convective heat loss.

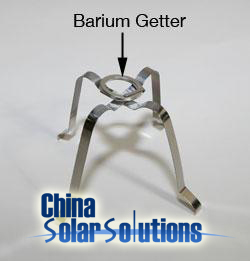

In order to maintain the vacuum between the two glass layers, a barium getter is used (the same as in television tubes). During manufacture this getter is exposed to high temperatures which causes the bottom of the evacuated tube to be coated with a pure layer of barium.

This barium layer actively absorbs any CO, CO2, N2, O2, H2O and H2 out-gassed from the tube during storage and operation, thus helping to maintaining the vacuum.

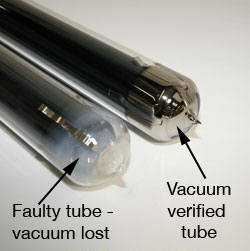

The barium layer also provides a clear visual indicator of the vacuum status. The silver colored barium layer will turn white if ever the vacuum is lost. This makes it easy to determine whether or not a tube is operating correctly.

Unlike other types of solar collectors, evacuated tube solar collectors still provide excellent results on cloudy days, This is because the tubes are able to absorb the energy from infrared rays which can pass through clouds.

Wind and low temperatures also have less of and effect on the function of evacuated tubes when compared to flat plate solar collectors due to the insulating properties of the vacuum. Glass evacuated tubes are aligned in parallel, the angle of mounting depends upon the latitude of your location.

In a North South orientation the tubes can passively track heat from the sun all day. In an East West orientation they can track the sun all year round. The shape of the tubes provides superior absorption when compared to flat plate collectors for a number of reasons:

- As the tube is round, the sun’s rays are always striking the tubes surface at right angles, thus minimizing reflection.

- If the collector surface is flat, the amount of solar radiation striking the collector surface is only at it’s maximum at midday when the sun is directly above the collector. In the morning or afternoon the sun’s rays strike the collector’s surface at an angle, and thus the amount of solar radiation that the collector is exposed to is reduced.

- Evacuated tubes, however, are round, and thus the amount of solar radiation striking the collector is relatively constant from mid morning to mid afternoon. This feature maximizes the total amount of solar radiation the collector is exposed to each day.

- Furthermore, the sun is always striking the tubes at an angle which is perpendicular to their surface thus reducing reflection.

|

|||||||||||||||||||||||||||||||||||||

Three Target Coating solar vacuum Tubes, it’s coating is made of AlN/AIN-SS/Cu. It has higher efficiency than AL/N /AL coating.

Product origin: China

Price terms:FOB

Payment term: T/T

Supply ability: 25000pcs/day

Mini order: 4500pcs

Delivery time: 1 5 days

Warranty: 5 years

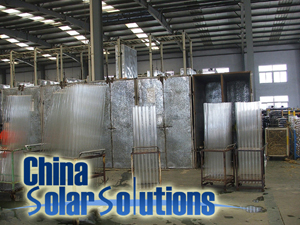

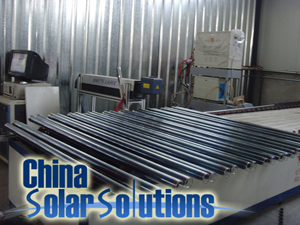

The Production Process of Solar Vacuum Tubes:

Solar vacuum glass tube production

Solar vacuum glass tube production

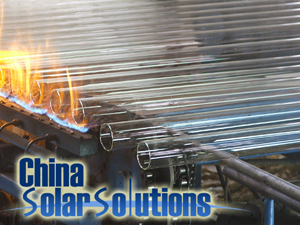

1. Forming Raw Glass Tubes

1. Forming Raw Glass Tubes

2. Cutting Tubes to Length

2. Cutting Tubes to Length

3.Tube Cleaning

3.Tube Cleaning

4. Inner Tubes Forming Round End.

4. Inner Tubes Forming Round End.  5.outer-tube-forming-bottom

5.outer-tube-forming-bottom

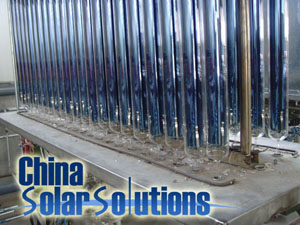

6. Absorbing Coating Process

6. Absorbing Coating Process

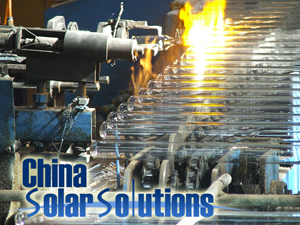

7. Fuzing Top of Tubes

7. Fuzing Top of Tubes

8.Sealing of Inner Tubes and Outer Tubes

8.Sealing of Inner Tubes and Outer Tubes

9. Evacuating Process

9. Evacuating Process

10. Pring Logo with Laser

10. Pring Logo with Laser

11. Packing Tubes

11. Packing Tubes

Material: borosilicate glass according to ISO3585:1991;

transmittance of borosilicate glass:0.92.

Absorbance of solar selective absorptive coating:0.94;

Hemispherical emittance:0.08;

Getter according to GB/T9505-1998.

Start-up temperature:no more than 25.

Start-up time:no longer than 2 minutes under normal sunshine.

Low temperature resistance:no breaks at-30

Heat impact resistance:no damages after over 3 times’alternative impacts of cold water below 25 and hot water over 90.

Pressure resistance:cam withstand 0.6Mpa.

Hail resistance:no damage by the impact of Φ25mm hail.

Appearance standard:the color of the selective absorptive coatings should be even,and the coatings should have no wrinkles and peelings.

The allowed tolerance of borosilicate glad tube’s diameter should be in accordance with ISO4803:1978.

camber of the borosilicate glass tube should be no more than 0.3%.

The translation the borosilicate glass tube,which is 40-60mm away from flange end,should be round.

The ratio of the longest to the shortest radial dimensions of the borosilicate glass tube should be no more than 1.02.